1,4-Butanediol started attracting attention not long after the rise of industrial chemistry. Chemists first created it through hydrogenation of succinic acid decades ago, and by the 1950s, manufacturers backed by post-war chemical booms began pushing for larger-scale production due to its use in fibers and polymers. Expansion kept pace with global manufacturing needs, especially for materials that defined new transportation and construction methods. Early on, the discovery brought hope for more affordable, tunable materials, and the history of 1,4-Butanediol reflects more than laboratory achievement. It represents a shift into industrial chemistry fueling economies and laying the groundwork for smarter material science.

1,4-Butanediol presents itself as a clear, thick liquid at room temperature, carrying little odor. In industrial circles, it serves as a crucial component for making everything from spandex fibers to plastics and solvents. Many businesses stake a good portion of their supply chains on reliable access to this substance. Ever since producers sharpened the downstream processes, 1,4-Butanediol has touched most modern infrastructure categories, operating quietly behind consumer products and engineering feats alike.

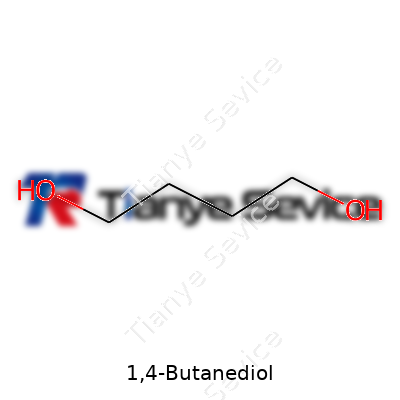

Chemically, it offers a straight-chain structure holding four carbons bridged by hydroxyl groups at each end. With a melting point a little below 20°C and a boiling point well across 200°C, this substance stays stable under many process conditions. It dissolves in water with ease, which supports its function as a solvent and intermediate. The reactivity comes mostly from those terminal hydroxyls, which open up countless modification routes for further chemistry. Its density and viscosity at room temperature let it blend well with other feedstocks or additives, a fact that manufacturers have leaned on for years to meet precise output requirements.

Producers usually stamp 1,4-Butanediol with clear technical specs. Purity rates regularly reach 99% or above. Impurities, if present, typically stay below 1%, and most industrial listings spell out moisture content, color (measured in APHA units), and acidity to help buyers compare batches. Many companies upload Safety Data Sheets (SDS) and technical bulletins, outlining hazard codes, storage advice, and basic toxicological data. Good storage means keeping drums tightly sealed and away from open flame. Regulatory standards in major markets require precise labeling, including batch traceability and hazard pictograms under global harmonized systems.

Early manufacturers started with acetylene and formaldehyde, combining the two under copper-based catalysts to form butynediol, which then got hydrogenated to the final 1,4-butanediol. Lately, biobased routes have made headway. Some new systems turn renewable sugars or alcohols into butanediol using genetically tweaked microbes. This movement away from fossil fuel feedstocks taps new market demand for green chemicals and can help cut emissions from manufacturing. Production scale runs depend on high-pressure reactors and careful purification steps, but innovations keep pushing toward cleaner, less energy-hungry protocols.

The chemical backbone of 1,4-Butanediol acts as a springboard for many reactions. It responds readily to oxidation, dehydration, and esterification. Turned into tetrahydrofuran (THF) through dehydration, it becomes a key solvent for polymers like spandex. Esterification gives rise to polyester resins or plasticizers critical for packaging, automotive, and electrical goods. Other reactions add in halogens or short chains that tailor the product for specialty uses. R&D labs keep finding routes to new polymer networks or flexible molecular designs, guided by fine-tuned processing controls over those reactive hydroxyl points.

Among chemists and industry pros, 1,4-Butanediol often goes by BDO. Catalogs or process sheets may list it as tetramethylene glycol, 1,4-dihydroxybutane, or just butane-1,4-diol depending on the locale or regulatory language. Product lines sometimes adopt trade names that reflect purity, intended application, or registered brands, but the core chemical identity anchors naming systems worldwide.

On the shop floor and inside labs, safe handling earns top priority. Workers suit up with gloves, goggles, and, if needed, full face shields since 1,4-Butanediol can irritate skin or eyes. Inhalation risks track close behind—good fume hoods or exhaust fans help control exposure, especially during high-temp operations. Storage rules call for cool, dry spaces with good ventilation. Fire risk may seem low, but spills on hot surfaces or open flames can flash up vapors. Spill kits stay on hand, and training routines walk staff through containment and clean-up. Beyond individual sites, both US and European regulators enforce workplace exposure limits and transportation rules, helping to keep supply chains steady and safe.

Polymer production claims the largest share of 1,4-Butanediol use. Makers of spandex draw on its ability to link up in long, stretchy chains—turning BDO into polyurethane fibers found in workout gear, medical textiles, and stretchable fabrics. Electronics companies need it for circuit coating polymers. It shapes the performance of engineering plastics and automotive parts that carry the weight, heat, and vibration of real-world use. Pharmaceuticals and cosmetics depend on high-purity BDO for solvent or carrier functions in everything from creams to capsules. In some factories, 1,4-butanediol helps clean precision metal parts before assembly or coats cables meant for outdoor installation.

R&D groups in universities and firms never ease up on looking for better ways to use and make BDO. One offshoot involves biotechnological production methods, where researchers explore new enzymes and pathways that lower the cost and environmental impact of synthesis. Improved catalysts and continuous-flow reactors promise to lift both yield and safety. Polymer scientists probe for next-generation plastics that combine BDO with renewable feedstocks or recyclable structures, aiming for greener construction materials and lighter car bodies. Teams also study how minor tweaks to the molecule can boost plastic flexibility, resistance to weathering, or ease of processing—all driving the market into new uses.

Concerns about toxicity followed BDO almost from the start. Swallowing moderate doses can produce sedation or even lead to coma because the body breaks it down into gamma-hydroxybutyric acid (GHB). Misuse cases have sparked regulatory moves to control access in some regions. At lower exposure, workers mostly face mild but real risks of skin or mucous membrane irritation. Chemists test for breakdown products in wastewater and living bodies, ruling out buildup that can hurt people or wildlife. Animal testing and occupational health studies build the base of knowledge for safe exposure limits, and more advanced toxicology now relies on cell cultures or computational tools to predict harm faster and more accurately.

Looking ahead, BDO’s future ties closely with global pushes for sustainable manufacturing. As customers press for plastics that won’t outlast their use, new chemistry around BDO can bring better recycling or upcycling. Lab trials in North America, Europe, and Asia all hunt for faster, cleaner synthesis, including bioconversion of plant sugars or mixed waste streams. Industry giants and nimble startups sense room for safer solvents and high-performance fibers, especially if cost and regulation line up. Digital tools in chemical engineering speed up design of new modifications with real commercial promise. Medical and electronics sectors keep feeding the hunger for reliable, high-purity feedstock, turning 1,4-Butanediol into a bellwether for smart, safe, and sustainable chemistry over the next decade.

People rarely think about the chemicals that support their daily lives. 1,4-Butanediol, often called BDO for convenience, goes under the radar for most. Still, it shapes plastics, fibers, and plenty of products that folks use every day. If you have ever pulled on a stretchy sweatshirt or hopped into a car, chances are BDO had a hand in making those items.

BDO supports the production of thermoplastic polyurethanes and spandex, two materials with serious demand. Polyurethane foam cushions seats in cars, supports sports equipment, and even pads furniture. Spandex, known for giving leggings and swimwear their stretch, also comes from a reaction involving BDO.

Resins, adhesives, and coatings also depend on BDO as a building block. If someone has ever worked on house repairs or painted exterior wood, they’ve probably seen the benefit—durable and long-lasting results don’t just happen by luck. These products must resist moisture, sun, and friction. BDO helps make these properties possible.

This chemical shows up in medicine, electronics, and cleaning supplies, too. Companies chain together BDO molecules in different ways, spinning out solvents that can dissolve stubborn stains or clean electronics without causing damage. It helps deliver prescription drugs in liquid form, keeping things stable so people get the exact dose they need.

BDO’s benefits reach far, but its power holds risks when handled carelessly. People sometimes abuse BDO because the human body can turn it into gamma-hydroxybutyrate (GHB), a substance linked to illegal recreational use and overdose dangers. The appeal comes from its intoxicating effects, yet the real danger hides in dosing mistakes—accidental poisoning and even death sit at the edge of any misuse.

Big chemical companies and regulators keep a close watch. Factories label BDO clearly and stick to rules for storage and shipping. Most folks don’t come near pure BDO unless they work in a related industry. Everyday exposure drops to near zero for regular shoppers, who see only the finished goods that BDO helped create.

Growing up in a town near several manufacturing plants, I watched how local firms handled chemicals. Strict training, safety drills, and regular checks stood as the norm. That focus on care became a point of pride—mistakes cost real people. It takes more than laws to keep people safe; it takes commitment on the ground and respect for what these chemicals can do.

Any solution that cuts the risks linked to BDO starts with education and transparency. Manufacturers should keep sharing what goes into household goods and talk openly about the precautions around chemical use. Government agencies play a part, but the best defense always comes from the shop floor to the truck drivers to the warehouse staff—all keeping safety in mind.

Consumers want greener alternatives, and researchers keep searching for safer replacements or better recycling options for BDO-based products. Plant-based feedstocks and improved supply chain controls offer hope for smaller footprints, safer workplaces, and tighter control on misuse.

BDO helps power modern manufacturing, but everyone benefits when companies, workers, and customers pay attention to both its power and its pitfalls.

1,4-Butanediol isn’t found in most home supply cupboards, but many people working in labs, factories, or the chemical industry come across it. It’s a colorless, slightly oily liquid with the kind of nondescript smell that makes it easy to underestimate. This chemical shows up in things like solvents, plastics, and even in some industrial cleaning products. But just because it’s familiar in certain workplaces doesn’t mean it’s harmless.

Breathing in its vapors, letting it touch the skin, or swallowing it can all lead to trouble. Workers have reported dizziness, headaches, and nausea after handling 1,4-butanediol without protection. In high enough doses, it depresses the nervous system, almost like alcohol but much riskier. Reports from poison control centers link hospital visits to accidental and intentional ingestion. Some people have even ended up with lasting neurologic problems after exposure.

Treating 1,4-butanediol exposure requires medical attention because the body converts it into gamma-hydroxybutyric acid (GHB). GHB can knock someone out, slow their breathing, or cause them to slip into a coma. It doesn’t take much more than curiosity or a poorly labeled bottle for a major accident.

Even if someone isn’t swallowing it, spills onto bare skin can lead to irritation. Eyes take an even harder hit; even a splash can cause severe pain and damage. Protective goggles and gloves aren’t just recommendations—they’re necessities. Nobody wants to learn this lesson the hard way.

Spills don’t just stay put. Since 1,4-butanediol dissolves easily in water, it travels quickly in soil and waterways. That trait creates risks for water systems and wildlife. A 2022 report from the European Chemicals Agency points out that it’s not particularly persistent, but that doesn’t let users off the hook—acute toxicity for fish and aquatic invertebrates has sparked reviews around safe disposal and containment.

Most workspaces using the chemical need well-ventilated storage areas. Safety showers and eye wash stations nearby cut response times if something goes wrong. Inexperienced workers tend to underestimate a clear liquid sitting in a drum. Training goes a long way. During my own time in a research lab, only one chemical caused a full team lockdown in a tiny storeroom. That was 1,4-butanediol, after someone spilled a beaker while preparing samples. We spent half a shift cleaning and filling out incident reports.

Regular inspections for leaks, updated labels, and strict enforcement of personal protective equipment policies help avoid surprise encounters. Employees need to feel comfortable asking about safety before starting a new process involving unfamiliar chemicals, especially one as potentially dangerous as 1,4-butanediol.

Quick, practical solutions start with access to clear information. Fact sheets at the point of use, annual safety refreshers, and basic first aid training equip teams to better respond. Storage in tightly sealed, clearly labeled containers lowers the chance of accidental exposure. Partnering with environmental services for chemical waste keeps 1,4-butanediol out of municipal water.

Manufacturers and facilities dealing in large amounts must contribute to public health efforts, not just internal safety. In the end, knowing the chemical’s risks removes the false sense of security that can sneak in over time. Responsibility and respect for hazardous materials always matter.

Some chemicals demand respect long before they reach a lab bench. 1,4-Butanediol makes this list through reputation alone. I remember hauling drums of the stuff across a warehouse floor, sweating over the placards and paperwork. It's not just the sharp, faintly sweet smell—it’s the knowledge that this clear, oily liquid can react if treated carelessly.

Excess heat and moisture cause headaches with most industrial solvents. 1,4-Butanediol is no exception. Stash it somewhere cool, away from direct sunlight or heat sources. Temperatures should stay under 30°C. Heat speeds up degradation. Worse, it raises the odds of a pressure build-up inside storage containers. I’ve seen tiny leaks lead to big messes—slippery pools that threaten everyone’s safety. Why risk flare-ups when air conditioning or good insulation fixes the issue?

Humidity brings another set of troubles. Water sneaks in wherever it can, opening doors for unwanted hydrolysis and impurity buildup. Dried air—either through desiccant units or well-maintained dehumidifiers—works wonders for keeping that liquid pure. I once watched a poorly sealed drum draw in moisture, fogging up inside and gumming things up downstream for a week. Desiccant packs and routine checks prevent that headache.

Never store this chemical anywhere near strong oxidizers, acids, or bases. Mix-ups or spills become dangerous fast. In a facility I worked for, a simple shelf mislabeling put oxidizers next to a batch: staff caught the mistake just in time. Segregation isn’t just regulatory box-ticking. Separate rooms, color-coded barrels, and clear signage go a long way toward stopping small mistakes from turning into emergencies.

Ventilation matters, too. Vapors don’t go easy on lungs or eyes. I learned the hard way during an unplanned vent pipe inspection—one whiff left me lightheaded and coughing. Fire marshals taught us to limit vapor build-up using open-air racking or strong mechanical systems. No one likes remembering the smell of a chemical burn in their nostrils or hazard alarms blaring.

Drums and tanks made from stainless steel, high-grade plastics, or glass keep this liquid under control. Old, pitted, or corroded containers leak or leach foreign materials. Last summer, a cracked gasket on a polyethylene drum let fumes escape, triggering an alarm, shutting down production, and wasting a lot of raw material. Invest in high quality—and check caps, seals, and valves with every delivery. It pays off in peace of mind and saved inventory.

People cause problems more than chemicals. Poor training opens the door for unsafe shortcuts. I’ve seen the difference it makes when staff follow clear protocols, use secondary containment, and wear gloves, goggles, and proper clothing. Regular drills and refreshers keep routines sharp. Spill kits and fire extinguishers should always sit within reach, and logs or digital monitors track conditions daily.

Following storage rules for 1,4-Butanediol isn’t just red tape or legal answerability. It means protecting people, products, and equipment against avoidable risk, saving money and lives in the long run.

1,4-Butanediol, or BDO, lurks in a surprising number of industrial products. Folks working in factories or handling solvents might bump into it more often than most realize. It acts as a solvent and is used to make plastics, elastic fibers, and some household cleaners. Problems start when BDO enters the human body. Swallowing, breathing in, or getting it on your skin brings trouble.

Inside the body, BDO turns into gamma-hydroxybutyrate (GHB). GHB works as a central nervous system depressant and has been linked to sleep disorders, unconsciousness, and in higher doses, troubles with breathing or even fatal overdoses. Researchers have warned for years that regular or significant exposure can cause symptoms ranging from nausea, drowsiness, and confusion to slower heart rates. I’ve seen stories from ER doctors who talk about patients passing out unexpectedly after accidental exposure in a work setting.

Evidence shows people who handle BDO often can feel dizzy or irritable, and sometimes their vision blurs. If someone takes in a large dose, whether by mistake at work or out of curiosity, life-threatening complications can follow. Slow breathing, loss of consciousness, and lasting memory problems show up in hospital reports. Even a bit of BDO can ruin a shift, especially for workers who have to keep sharp focus or operate heavy machinery.

Skin contact is no picnic either. BDO can cause red, irritated skin, and in some cases, burns where the solvent soaked through. I once spoke to a machine operator who got a drop of solvent on his wrist on a hot summer day. The redness and swelling didn’t quit for almost a week. For workers without easy access to safety training or gloves, this risk climbs even higher.

Most families won’t find BDO in their bathroom cabinet, but problems still pop up. Folks have used it—sometimes without knowing—for its intoxicating effects. In such cases, it can act almost like a street drug. Emergency rooms have seen cases where teenagers end up in critical condition after using it recreationally. That pattern keeps repeating in headlines about accidental poisonings and overdoses.

Environmental leaks can add to the risk. Plants or transport accidents can send BDO into the air or water. The Environmental Protection Agency keeps an eye on these sites because even small spills can pose threats to communities. Drinking water contamination could leave families sick with stomach pain, muscle weakness, or confusion.

Employers play a big role in keeping people safe. Safety training can make a difference. Gloves, eye protection, and fume hoods reduce the chances of BDO touching skin or getting breathed in. Some companies use sensors to check BDO levels in the air, and clear warnings where solvents get stored do more than just check a regulatory box—they help save lives.

If someone feels sick or dizzy after possible exposure, doctors need to know right away what chemicals came into play. Quick response saves lives. In my own work, clear labeling and honest conversations about chemical risks make a difference. Families living near chemical plants should push for regular inspections and real-time smog monitoring.

Accurate information empowers people to watch out for their own health as well as neighbors. When communities pay close attention to where chemicals get stored, and workers speak up about safety, fewer people end up in the hospital from a solvent they barely heard of.

1,4-Butanediol, or BDO, shows up in places most folks would never expect. It acts as a building block in plastics, fibers, solvents, even some health supplements. Trouble starts when it lands in the wrong place: a drain, a dumpster, or worse yet, nature. Once BDO escapes into sewer systems or groundwater, it can bring serious harm to fish, bugs, and even people downstream, especially since it breaks down into gamma-hydroxybutyric acid (GHB), a controlled substance. I remember a neighbor who tossed out old cans of chemicals in the trash. Few things stick with you like the slow, uneasy gray sheen that trickled from their bin into the gutter after a rainstorm.

No matter how tempting, pouring BDO down the sink or tossing it in the trash means shifting the risk to someone else—janitors, city waste workers, landfill operators, or even kids who play near a leaky garbage pile. Wastewater treatment plants try to pull chemicals out of sewage, but many solvents and industrial leftovers slide right through. This isn’t just an environmental issue; it’s a public health risk. I’ve watched communities get hit with boil-water notices after heavy rains washed toxins from storage sheds and dumpsites into streams and rivers. The fix always costs ten times more than keeping the junk out in the first place.

Expert advice on hazardous chemicals comes down to careful planning and respect for each step. 1,4-Butanediol counts as hazardous waste under most local and national systems. Never try to dilute or mask BDO with household chemicals; mixing can set off unpredictable reactions. Instead, keep it in a leak-proof, clearly marked container—ideally the original one. In all my jobs, whether working a lab bench or helping at a recycling event, the folks who followed this step kept both workers and the environment much safer.

Take that container to a certified hazardous waste disposal site. Most towns and counties hold collection days for garage chemicals, solvents, and old paint. The staff wear thick gloves, goggles, and know exactly how to package chemical waste before shipping it to a licensed incinerator or chemical treatment plant. Nobody cuts corners, since messing up means fines, health risks, or a plant shutdown. I've seen firsthand how these extra steps build trust with the public and keep groundwater safe.

Some countries already treat 1,4-butanediol as a controlled substance, given its potential for misuse. Rules are getting stricter, which pressures companies and users to keep better records and track where waste goes. At the job site, we limit chemical purchases to what we truly need—no big leftovers just gathering dust. That habit cuts down on disposal costs, inventory headaches, and the ultimate risk of accidental release. Schools and small businesses now follow suit, using monthly audits to keep chemicals out of classrooms and off the streets.

Cities can keep expanding community disposal events and educate everyone—high schoolers, hobbyists, business owners—about the dangers of tossing solvents or BDO down the drain. Manufacturers can switch to greener solvents where possible and test on-site recycling instead of landfilling. Every bit of effort upstream pays off by saving cleanup costs, protecting drinking water, and keeping neighbors out of harm’s way. The more carefully 1,4-butanediol gets handled, the fewer stories we’ll tell about environmental messes and toxic chemical accidents.

| Names | |

| Preferred IUPAC name | butane-1,4-diol |

| Other names |

1,4-Dihydroxybutane

Tetramethylene glycol BDO Butane-1,4-diol |

| Pronunciation | /ˌwʌn.fɔːr.bjuːˈteɪn.daɪˌɒl/ |

| Identifiers | |

| CAS Number | 110-63-4 |

| Beilstein Reference | 1720240 |

| ChEBI | CHEBI:16987 |

| ChEMBL | CHEMBL1357 |

| ChemSpider | 8219 |

| DrugBank | DB02166 |

| ECHA InfoCard | 03b7d9b4-3a53-4e67-a679-5f429866b69d |

| EC Number | 203-786-5 |

| Gmelin Reference | 77890 |

| KEGG | C00976 |

| MeSH | D017245 |

| PubChem CID | 8064 |

| RTECS number | EI9646000 |

| UNII | 6X9OC3H4II |

| UN number | UN 1147 |

| CompTox Dashboard (EPA) | DTXSID4020202 |

| Properties | |

| Chemical formula | C4H10O2 |

| Molar mass | 90.12 g/mol |

| Appearance | Colorless, oily liquid |

| Odor | Odorless |

| Density | 1.017 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.96 |

| Vapor pressure | 0.01 mmHg (20°C) |

| Acidity (pKa) | 14.5 |

| Magnetic susceptibility (χ) | -60.5 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.445 |

| Viscosity | 80.5 mPa·s (25 °C) |

| Dipole moment | 2.42 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 197.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -537.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2544.6 kJ/mol |

| Pharmacology | |

| ATC code | D04AA17 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P305+P351+P338, P337+P313, P370+P378 |

| NFPA 704 (fire diamond) | 1,2,0 |

| Flash point | > 121 °C |

| Autoignition temperature | 370 °C |

| Explosive limits | 2.0–11.8% |

| Lethal dose or concentration | LD50 Oral Rat 1,525 mg/kg |

| LD50 (median dose) | 1,530 mg/kg (rat, oral) |

| NIOSH | CN3675000 |

| PEL (Permissible) | 50 ppm |

| REL (Recommended) | 50 mg/L |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

2,3-Butanediol

1,2-Butanediol 1,3-Butanediol gamma-Butyrolactone Tetrahydrofuran Succinic acid Butanol |